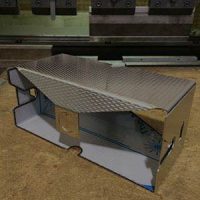

Thanks to high precision machinery, Alfa Inox is now a leader in the laser cutting industry.

Quality, precision and speed are the characteristics that distinguish our cutting work and the execution of details.

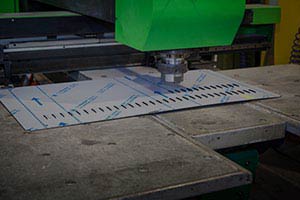

Charateristics:

Laser cut 4000 watt with 4000×2000 mm working range and automatic pallet changer.

Our machines are able to cut up to 15 mm thick in stainless steel and iron and 3 mm thick for aluminum. Our technical office manages the process thanks to cad/cam software.